I used brass (this time) because I was wearing out the Graph Tech Tusq XL nuts playing everyday (in the recording studio for hire) and gigging nightly.

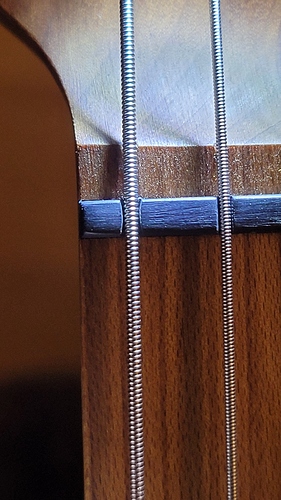

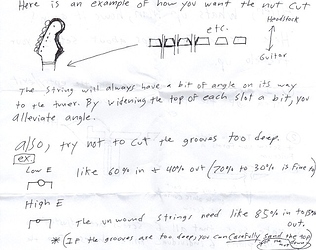

But the material used doesn’t matter…what matters is getting the pull straight through the nut with no lateral misalignment. If you can achieve straight pull, then nut slot width needs only to be approximately .004" above string gauge, which is my preference. But, on many guitars, even ones I am seeing coming out of Fender in Corona, the lateral misalignment is so acute that the setup techs are cutting the slots wider in an effort to compensate and it doesn’t fix the problem.

Although Warmoth CNC’s their tuner holes, there are variations in tuner placement based on where the neck is placed under the clamps by the operator and in some cases, I’ve had to plug and redrill Fender USA, Warmoth and Musikraft necks to correct the misalignment issues.

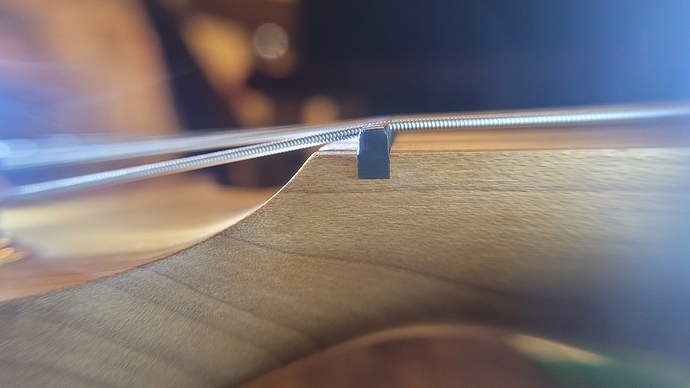

The slots also need to have a curved bottom (the Stewie-Mac files have this profile) and the last 1/3rd of the slot needs to “fall away” from the string.

I’m using vintage tuners (Gotoh SD-91) with a Gibson/Kluson on the low ‘E’ to improve string angle through the nut. Locking tuners only correct string wrap anomalies, but they are totally unnecessary. String trees are not needed with the vintage, short-post tuners.

If you are using long-post tuners, like the Grover 136G6, then a string tree matmy be needed on the b/e strings. However, it’s important to use a roller tree and a small spacer to reduce the downward pressure across the nut slot…