So it appears that McMaster is backordered on the 1/4" screws. Would the 5/16" version work? Will that extra 1/16" cause that much of a problem or should I just wait? I ask because I can’t seem to find anywhere else that sells this screw with the wider head like McMaster does.

Screws that are a tiny bit longer should be no problem. As long as they’re same diameter. In general there are probably lots of small variations with the parts that could work fine, so usually recommend giving it a try if you find something almost but not exactly the same as the ones we used. Worst case typically you’re only out a few bucks if it doesn’t work!

Ha, yes, I discovered this as well. All of the parts, tools, and printed pieces have arrived as of today and the screws are backordered…

The 5/16" screws worked just fine for me.

Thanks sagacious one. The 5/16"'ers will arrive on Friday.

No prob. I was very impressed at how fast they shipped everything.

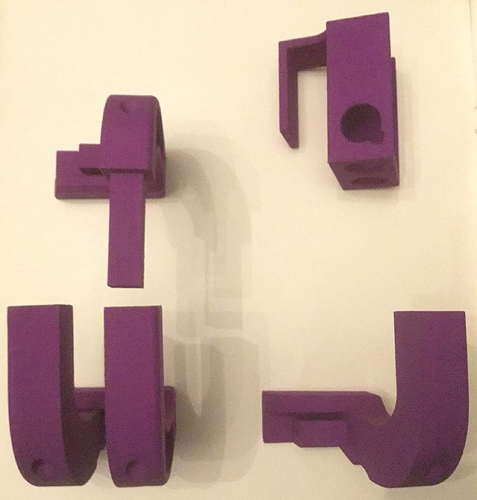

Oooh, purple, nice! I opted for the classic red, but it was a tough choice.

Thanks! Yeah, purple makes me play better.

Or would, if Shapeways sent me the right parts. I got a duplicate of one piece and I’m missing another one. I’ve contacted support but doesn’t appear I’ll be fully magneted until this is resolved. Oh well.

The Revenge of the Fifth is nigh!

Dude! That’s lame! Hope they get it resolved for you quick…

Thanks Sage. Replacement should be on its way. Onward and upward!

For what it’s worth, a whole new printing arrived end of last week. Now I wish I had the missing piece, I could build two…

At any rate, they made good on it, so I’m pleased.

Egads, those rods… I’d add a tapping bit to the shopping list for the next person…

But alas, slow motion still…!!!

I will probably take it apart for additional sanding and threaded rod replacement. It’s literally hanging together by a few threads. For now though, back to playing! Thanks again all. Peace.

Nice, looks good!

Did you use the hollow plastic rods? Should be able to just screw the screws right in, does take some force but should be no tapping required!

Yeah the more you sand / file all the places where the parts slide together, the smoother it should end up

Thanks Brendan! Maybe the composition of the rods was different than what you worked with? I ordered according to the list but sounds like I had a very different experience than what you did. Ultimately had to drill out the bore to get it happening.

Overall the design is very cool! Well done, sir, sirs!

An idea… Drill a tubing sized passage into a chunk of wood for clamping to a workbench and stabilizing the tubing while fiddling with screws… Now where did I put the charger for the drill… Makes me wonder what other grippers, holders would help a guitarist protect their hands while working on this kind of thing.